Description

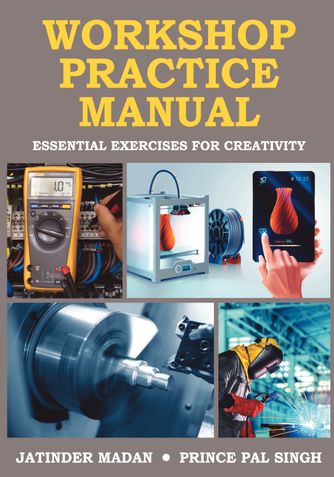

Workshop practice course is introduced in undergraduate engineering programs to the freshman in several countries. The objective of this course is to provide the students a practice-based exposure to the most basic manufacturing or workshop processes, such as carpentry, fitting, foundry (or casting), welding, sheet metal, electrical, electronics, smithy and forging, and machining. Although there have been notable developments in the manufacturing technologies, with many new manufacturing processes being introduced, the above-mentioned processes are still relevant and important to understand newer processes. Therefore, exposure to the workshop practices is required for the students in their first year of engineering programs. Further, in recent years, additive manufacturing or 3D printing technologies have also gained importance, which also needs to be introduced to the students in their first year itself so that they can use it for exercising creativity in remaining years of their program. Power tools, such as hand drills are also important to perform many tasks. The book covers above mentioned conventional workshop practices, and the topics of power tools and 3D printing.

This book is about practice. Therefore, selected practical exercises are given at the end of each chapter along with the detailed procedure. A response sheet where the learners can answer to specific questions after they complete the given exercise has also been provided. A number of illustrations have been used in the book for clarity and understanding to make the learning experience enjoyable.

Dr. Jatinder Madan has teaching and research experience in mechanical engineering with a

focus on manufacturing engineering and allied topics. He received his Ph.D. in Mechanical

Engineering from IIT Delhi, New Delhi. He was a visiting researcher at the System

Integration Division of the National Institute of Standards and Technology (NIST),

Gaithersburg, MD, USA, during August (2011- 2013) and May – June 2019. He traveled

to the USA multiple times for participating in ASME’s Manufacturing Science and

Engineering Conference (MSEC), which is an international event of repute where

scientists from across the world showcase their manufacturing focused research work.

Currently, Dr. Madan is serving as Professor and Head of the Mechanical Engineering

department at the Chandigarh College of Engineering and Technology (Degree Wing),

Chandigarh, India. Dr. Madan has been instrumental in developing the workshops at his

college and has been an instructor for the Workshop Practice course to the undergraduate

engineering students. He has published several research papers in reputed international

journals and international conferences, supervised PhDs, Master’s Thesis and completed

funded research projects. He has research interests in Sustainable Design and

Manufacturing, CAD/CAM, Design Automation, Design for Manufacturing and

Assembly (DFMA), and Smart Manufacturing.

Dr. Prince Pal Singh is a mechanical engineer with specialization in manufacturing

engineering. He did M. Tech. in Manufacturing Systems Engineering from Sant Longowal

Institute of Engineering and Technology, Longowal, Punjab, India and B. Tech. in

Mechanical Engineering from Kurukshetra University, Kurukshetra, Haryana, India. He

received Ph.D. in Mechanical Engineering with specialization in reconfigurable

manufacturing systems from I.K. Gujral Punjab Technical University, Kapurthala, Punjab,

India. He has taught several courses to undergraduate students of mechanical engineering,

such as manufacturing systems, workshop technology and manufacturing processes. His

current research focus is on manufacturing systems design, sustainable manufacturing, and

reconfigurable manufacturing systems. He has published many research papers in reputed

refereed journals and international conferences. He currently serves as Data Analyst in the

Engineering and Analytics Department of the Spyglass Analytics Software Private Limited,

Gurugram, Haryana, India.

The authors have contributed equally for preparing the manuscript.

Free Shipping

Free Shipping